PE Polymers

Ticinoplast uses only virgin grain suitable for use in the food sector. The selected raw materials allow to obtain a product free of any defects.

Storage in silos

Ticinoplast has invested in an automised resin transportation system to ensure the supply of the lines without overwhelming the physical work of the operators. In the last few years, we have invested in an automated system which emptys the bags, further reducing the residual load.

Dosage of components

The latest generation dosing systems installed on all lines allow to obtain consistent mixes overtime and to guarantee the specific requests. Special attention is placed on the addition of products, with the use of gravimetric dosers.

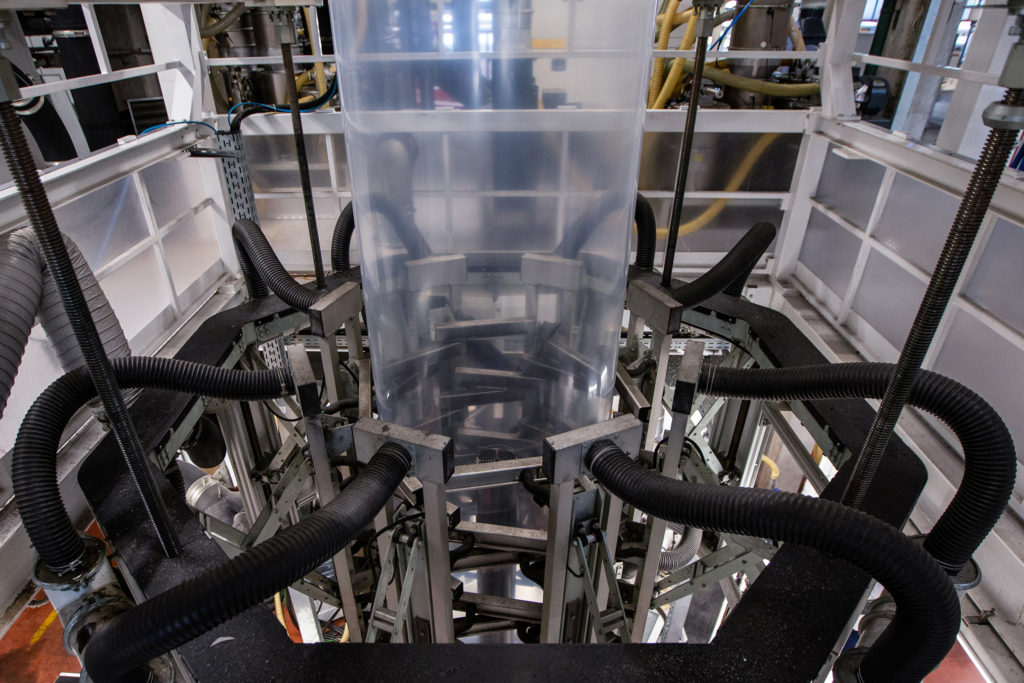

Extrusion

The dosed components are fused using high productivity extrusion screws blown into the line head. The use of cooling rings with feedback control systems allow to obtain perfectly planar coils with optimal thickness profiles.

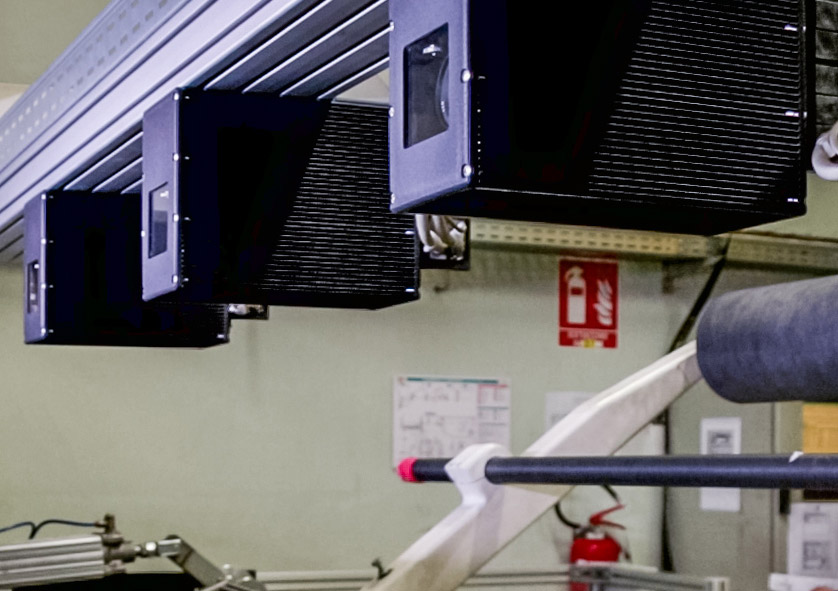

Quality control

Ticinoplast uses the most advanced quality control systems, to ensure the maximum qualitative level to the clients. Upon request, the reporting of the visual inspection of the reels is available.

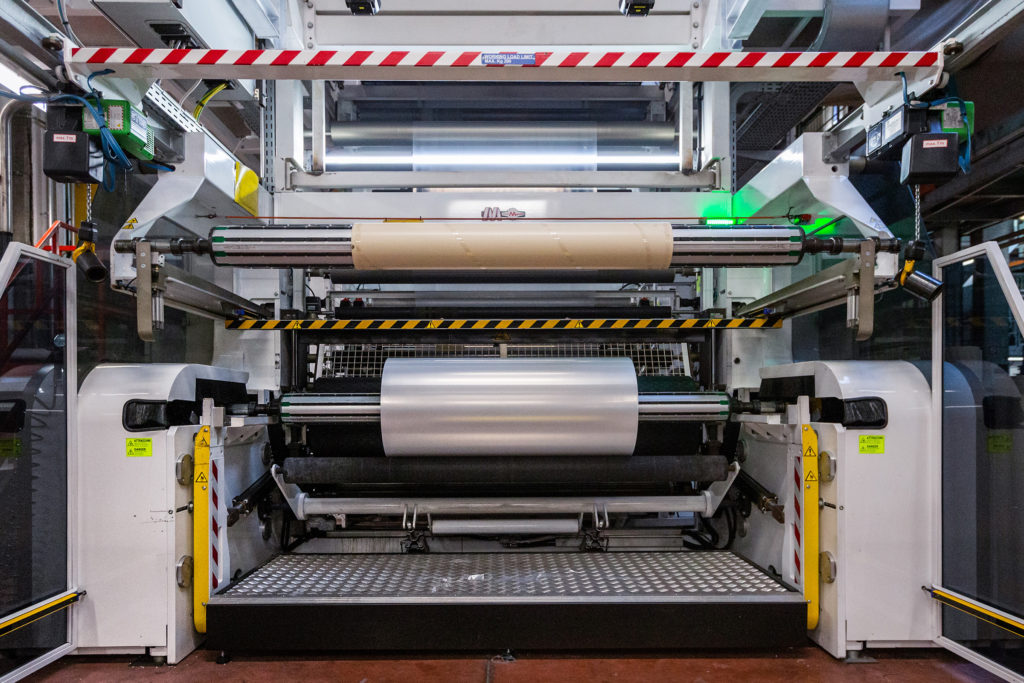

Collection of the films

The coils are wrapped with a constant control of the process parameters to avoid defects and to allow the clients an optimal and constant use of the entire coil.

Packaging

Special attention is placed on the internal handling systems and on automatic packaging, in order to protect the product until is it opened by the user.

Shipment

Ticinoplast has implemented a logistics network throughout the nation in order to offer the users the best possible service.