B100

A Rigid film, bio-polyester base, characterised by good clearance, printable also in rotogravure and suitable to be used as an external layer of a compostable laminate. This film can be lacquered and metallized to achieve excellent O2 and VWTR barrier results.

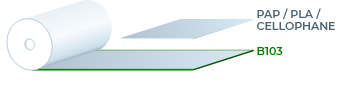

B103

A soft and extremely low sealing film with excellent mechanical characteristics, suitable to be coupled in conjunction with the B100 as an internal layer of a compostable laminate.

A soft, low-sealing film to be used for monofilm and lamination applications as a sealing layer to other compostable substrates such as cellulosic films or PLA base.